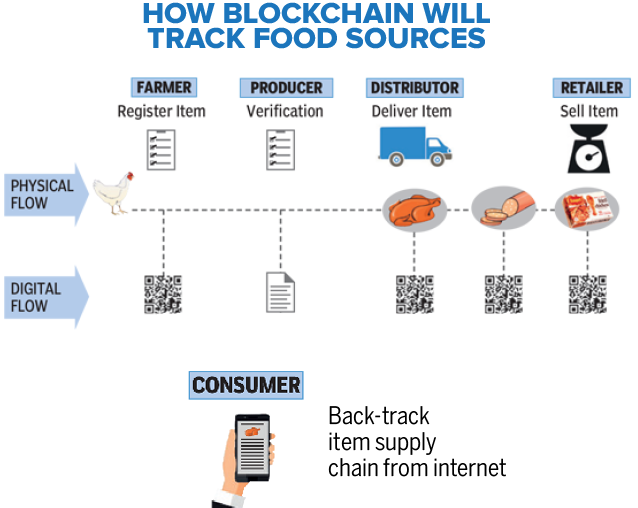

The Agriculture Blockchain is here, today.

In my travels throughout the agriculture industry, I routinely talk to people who say things like “this tracking and tracing, and blockchain stuff is interesting, but it doesn’t affect me and won’t impact my business for many years in the future.” I can understand why they say that. So far, the agriculture supply chain has been fairly unaffected by the technological revolution that is hitting other industries. While on-farm technologies have started to take off – heck, we have fully robotic combines now that drive themselves – post-farm supply chain hasn’t seen the type of disruptive technology that others have.

Or so many people think. The reality, however is that these technologies are here, and they being deployed now, and those who do not implement them will be the buggy-whip manufacturers of the future.

As an example. On Sept 24, 2018, Walmart announced that it will require all suppliers of fresh, leafy greens to trace their products back to the farm using blockchain technology.

“All fresh leafy greens suppliers are expected to be able to trace their products back to farm(s) (by production lot) in seconds – not days,” the company said in a letter to suppliers. “To do this, suppliers will be required to capture digital, end-to-end traceability event information.”

Direct suppliers are expected to have these systems in place by Jan. 31 and all “end-to-end” suppliers are expected to comply by the end of September 2019.

Meanwhile, national dairy cooperative Dairy Farmers of America (DFA) announced Sept. 25 that it is starting a pilot project intended to increase supply chain transparency and better connect farmer owners with customers.

“Consumers today want to know where their food comes from and blockchain technology, gives consumers real-time data, which can really help increase trust and confidence about food production from start to finish,” said David Darr, vice president sustainability and member services at DFA, in a press release.

Janette Barnard, sales and marketing director at DecisionNext, shares her expertise on digital value chains in agriculture, including blockchain technology.

“As the flow of information through the value chain becomes increasingly valuable, capturing, transferring, and using data will be a critical evolution in the grain industry,” notes one of her presentation previews. “In this session we’ll explore the dynamics around this shift and the skills, processes, systems and tools from predictive analytics to blockchain that will enable first movers to gain an edge in this new digital world.”

The fact of the matter is that field-to-plate digital tracking, and blockchain technologies are already having an impact in certain segments of the seed, feed, food and grain supply chains – and this change is accelerating at an incredible pace. Those organizations that do not prepare today for what is already happening, but will most surely be ubiquitous only a few years from now, will get locked out of markets for their products as customers, like Walmart, refuse to accept product that is not part of the chain.

The good news is Agriflo is ready today for these and other requirements. Contact us to find out more.

Agriculture, What Next?

- What’s Next

Agriculture, What’s Next?

As technology becomes an increasing part of our everyday lives, more and more examples can be found in the agriculture world. A great example of this can be found in precision agriculture where farm machinery is getting connected to artificial intelligence and with websites and the management of big data.

It can even be found in the processing of seed, feed, food and grain where technology is beginning to play an important role in processing with new tools of (AI) artificial intelligence and blockchain.

This technology can deliver instructions in a farmer’s native language, including when to sow their crops and has led to a 30% increase in yields for those farmers. This is an example of a successful ‘App’ which was created by using the Microsoft Cortana Intelligence Suite, which includes machine learning and is powered by people in order to create the optimal date/best time to sow.

Farmers who participated didn’t need to install any special apps on their devices and could receive the information via text messages. These farmers in India sowed their seeds early and the ‘App’ was especially helpful during monsoon season.

This is just one example of how AI can help farmers to actually utilize their seeds in an effective and timely manner to help them with increasing their yields.

Processors can use AI in a very similar manner, by learning how to effectively manage their plant’s times which will increase their rate of return on investment and/or increase their KPIs.

AI has the ability to examine the tasks that are being performed, look at the big data and then determine insights and make predictions. It can be as simple as taking a “snapshot” picture of a business and giving a diagnosis of what’s occurring in the plant and what needs to happen. Or it can be more complex with many different aspects of many different controls, ultimately helping your business to ensure that there is excellent quality in the plant.

Ultimately AI is the automation of tasks. These tasks and the information garnered from them will never get missed. AI doesn’t seek out the replacement of key individuals in your process, instead it enhances their industry and experience knowledge and allows better and innovative decision making which helps companies become highly effective with increased KPIs.

If you would like to learn more about Agriculture Technologies and Agriflo. Please contact us

Fully Integrated Systems

Fully Integrated Systems

What are the best reasons to have Fully Integrated Systems in Agriculture?

Fully Integrated Systems reduce the amount of re-entry and reduce the amount of re-work. By fully integrating your processes on the farm or in the processing facility, you are able to do more with less. By connecting the system to the shop, you can receive real-time information and gain the ability to make decisions very quickly which will increase KPIs. Within your facility this could be as simple as connecting your agris system to your accounting system or it could be as simple as having one central source of information. Studies have shown that manufacturers or processors can actually improve their business in terms of productivity and terms of financial gains by 30-40%.

Fully integrated systems actually help you in the tracing and tracking process, especially when the need is to quickly identify immediate issues. A closed loop system can actually minimize errors and allow you to work ON your business rather than IN your business.

In order for a closed-loop system to be successful, three key features need to be addressed. People, Processes and Tools. If you train your people to work within the closed loop system you will reduce re-work and reduce re-entry and this allows you to have the appropriate tools for decision-making to happen in a quick timeline. It will also help you uncover errors faster and give you the ability to deal with them as in a timely manner. A closed loop system can actually help you and your employees have a complete snapshot of your company.

If you would like to learn more about fully integrated systems or Agriflo. Please contact us

Agriflo & Fleet Tracker GPS Announce Partnership!

![]()

As part of our continuing dedication to enhancing and expanding the integration footprint of the Agriflo management solution, we are very happy to announce our partnership, and integration with the GPS tracking solutions provided by Fleet Tracker (www.fleettrackergps.com).

This partnership will allow users of Agriflo to have out of the box capabilities related to tracking the location/position, as well as meter/metrics on various types of equipment, such as Vehicles and Trailers. The practical implications of this are substantial, not only does this allow Agriflo to automatically determine that equipment is due for maintenance – and schedule that maintenance, but it also allows substantial improvements to fleet dispatch, tracking, turn-by-turn GPS instructions, proximity notifications, early and late arrival notifications, and much more.

We are excited about the opportunities this partnership opens for us, and our clients.

Some information about Fleet Tracker:

Fleet Tracker is family owned and operated and had been involved in Ag for generations.

We value the ideals and ethics in the Ag community. We have been in business since 2010 and have a technical background which relates well with GPS and the technology behind it. We also have experience in the installation process with helpful mechanical knowledge.

Our company sells GPS fleet and freight products, provides the installation and the service. We also maintain customers through support and training. Fleet Tracker offers a variety of GPS products from wired devices, wireless battery and disposable your company can find a solution that works for your needs. Our goal is to provide innovative solutions for the current and future needs of our customers.

We strive to continue growing stronger, supportive relationships in the industry.

For more information, please contact us.

Technology and Agriculture

Technology and Agriculture

Technology has drastically impacted Agriculture in many different ways over the last several years. Examples of this impact can be seen with the use of drones by farmers, Real-time analytics that can be pulled from precision Agriculture and even in Agri-processors who have Automation in their facilities to help receive grain with more efficiency.

With new technology moving in fast for Agri-Processing there is definitely an informational gap occurring between the processing plant and the office. This can detrimentally impact the company’s bottom line. This separation is like a fog (or White Space), where you and your employees really do not know what is happening in the fog at any given point in time.

Delays can impact:

- People

- Process

- Tools

These delays can be reflected negatively in inventory accuracy, operational efficiency or even compliance and food safety issues. Any of these problems are cause for concern , but what really hurts the processor is the inability for real-time decision making.

Communication:

Communications need to be linked between the plant and the office because when they are not your company creates White Space. With white space, a company’s communication becomes very “silo’d” with “me” centric tools and this can cause disjointed workflows. A great example of “me” centric tools are email clients such as Outlook or Outlook 365. These programs serve a purpose in our individual workflow and help us in our day-to-day flow, but as a team platform they can be quite limiting. The “me” centric tools cause a huge amount of repetition work, where employees are touching items 4-5 times, or reworking and reworking in order to push items forward. This cycle can lead to frustration at the end of the day, processes can be stalled and employees can feel that they are on a never ending treadmill with no forward momentum to complete tasks.

By connecting your “me” centric tools to workflow automation, accounting systems and even to your Customer forward facing CRM (Customer Relation Manager), it can improve your communication 10 fold, and allow you to be more proactive in your decision making.

Workflow:

If there is White Space between the Processing plant and the office there will be a definite impact on workflow. Delays in processing can impact the bottom line or the company’s key performance indicators (KPIs). The goal becomes reducing white space by connecting the tools, processes and people to the workflow.

This can be achieved by integrating existing tools to help you with the interoperability of the company. Or by reviewing your current needs and looking at your future needs to help you find tools that may be a better fit for your company. By closing the loop of the workflow, it will allow you to lean out processes, empower your people and more importantly, grow your business.

Getting rid of, or reducing White Space can be a challenge because of processes that may not have changed in several years or may be from a time where you were managing your business with much smaller sales volume. If so, this is the best time to review your processes, and see what needs to be changed, improved or even removed. If your company is planning to change processes one key point that will ensure higher rates of success is to engage your employees and team members in this process. They have the experience and likely know better than anyone else, what already works and what doesn’t.

Technology:

Challenges that can make existing problems worse is when a company runs to Technology and throws it at their problems hoping that it is a quick fix. This is a dangerous decision and often leads to failed technological implementations, or high staff turnover. If new technology is the solution for your company then it is wise to slow down before you speed up. There has to be a deep drive to review your company’s needs (People, Process and Tools). Luckily, there are tools that can help you with this review and will give you the extra knowledge to make an informed decision. It is always better to change things in small bite size pieces so that you can really see the outcomes and it will also provide your company time to adjust without hurting your business.

Agriflo Supports Agriculture In The Classroom

CRM Systems is a proud supporter of Agriculture in the Classroom [Manitoba]. Our very own David Lapp, shown here teaching on technology in Ag. Children have an inherent interest in plants and food, and this is a great way to bring agriculture professionals directly into the classroom – to teach, inspire and answer questions.

Agriculture in the Classroom–Manitoba (AITC-M) has been operating since 1988. AITC-M delivers curriculum-based programs, activities and resources for teachers and their students to learn more about agriculture and the role it plays in our province. AITC-M is part of Agriculture in the Classroom-Canada, click here to find out more.

AITC-M is a non-profit, charitable organization supported by sponsors and members who share the organization’s goal. Executive Director Sue Clayton works with the Board of Directors, staff, members and volunteers to develop and deliver the programs to Manitoba schools.

AITC-M’s Board of Directors is an elected board that represents a cross section of the industry. There are 15 members who exhibit a commitment and dedication to delivering an accurate, balanced and current message about agriculture. This is AITC-M’s ABC principle and it is on the membership’s behalf that the organization demands accountability to it.

The AITC-M organization will promote the development of critical thinking skills related to the businesses of agriculture, food, bioproducts and life sciences in all Manitoba students. In coordination with commodity and other industry related organizations, AITC-M’s programming, events and services will further develop future decision-makers and entrepreneurs.

Vision: Agriculture in the Classroom-Manitoba Inc. will lead in the development and distribution of accurate, balanced and current information for use as education resources in school curriculum.

AITC-M’s Core Objectives:

• To enhance awareness of agriculture in Manitoba schools

• To develop an appreciation and awareness of the importance of agriculture, socially and economically

• To explain the process of food and fiber production from farm to consumer

• To inspire interest in agriculture and agriculture careers

• To provide a supporting role to Manitoba Education and Literacy in the linkage of accurate agriculture resources to existing course curriculum

• To work collaboratively with industry partners to develop engaging, interactive agricultural experiences for youth

• To develop resources and programs with the guidance and expertise from agriculture and education communities

AITC-M has a variety of programming designed to create links between agriculture and the classroom. All our programming can be customized to meet a particular need, or we’ll work with partners to develop a new program.

Contact CRM Systems if you are interested in having us present to your school, club or troop.

CRM Systems supports several different community organizations, and we are always interested in finding more good organizations to partner with.

Why should we connect?

There are many different types of challenges facing those of us in Agribusiness; we have challenges with Customers, Producers and even getting our product in and out in a timely manner. Our decisions have to be quick and accurate, which means that our decisions have to be made in real time. The world appears to be speeding up and our decision making has to follow. The biggest problem is what information do we need to make real time decisions? You may have heard of concepts like Big Data, Internet of Things, connectivity, inter-operability and Industry 4.0. Which are the ones you should consider?

1) Connectivity:

In order to gather the best information, we need to make sure that we are connected. This works best in closed loop systems so that all the important information is being captured. In recent years the ability to have a closed loop system has become far easier with PLC (Programmable Logic Controllers) and Automation Controls on the farm and in the processors’ plant. If you haven’t already connected these areas then it should be a top priority, because once you connect these areas together it will allow you to understand how your company is working.

An issue of connectivity is that there can be a shifting constraint. A shifting constraint occurs when you start connecting the pieces to close the loop and unsurprisingly problems will be found in your current processes, these are the shifting constraints. As you tackle and resolve the constraints as you discover them you may notice a shift to a new constraint. This eye opening process will be resolved once all the problems are corrected, allowing a much more efficient process for your everyday activities. This may be a little bit scary or may take some time and effort from employees and management, but I always tell people it is better to slow down in order to speed up. The result will be totally worth it.

2) Inter-operability:

Inter-operability is different from connectivity because it may not be a seamless integration. The concept of inter-operability is knowing that you have data that could be used in your decision making but realizing that you may have to pull this information from the source using third party tools or the ability to export. This can be a small extra step. However, implementing this type of communication strategy, even if they are third party tools will allow you to get information and data that can be vital when making rapid decisions and allows you the ability to stop relying on historical information.

These types of solutions can have challenges because sometimes the pieces may not be able to pull the information that you really need or want. This is when a cost benefit will have to be examined and a decision will have to be made about if it is worth while to make small changes and put something in place to help with the capture of information. Or do you leave it until it makes sense to change in a big way. In either scenario, you will need to be gathering information to help you decide.

3) Big Data:

Big Data is a very popular concept in the business world today. The idea that we should always be plugged in and pulling information from all the sources we can is pervasive and encompassing. The idea is that – More information is always better! However, is this actually true? Sometimes this is not always the case. Companies and Individuals can experience a situation called Analysis Paralysis. This occurs when we are getting too much information and then we can not even fathom where to start. I have come across this situation multiple times, people believe that if they pull every bit of data that they will find some pattern, or trend that will give them the “A-ha moment” to solve their problems.

However, the trick to Big Data is knowing what we need to measure and then to start from there! Even if we only focus on our top three issues in our business, imagine how much of a benefit that would be! In this case you could actually do more with less!

In closing the key to success in connectivity and Big Data is to start small and work towards your goal! By taking off bite size pieces, it makes the goal of true connectivity achievable for any company.

Self-Service Web Portal

agriflo includes a highly functional self-service portal that can be used for customers, vendors and other 3rd parties.

agriflo includes a highly functional self-service portal that can be used for customers, vendors and other 3rd parties.

The portal is fully functional on Desktop, Laptop, Tablet and mobile devices.

Log in, update bin inventory, check on contracts, bookings and more. Update contact information – even check on the status of your payments. Its all possible with the agriflo Self-Service portal.

This short video explains some of the portal’s capabilities:

Producer / Vendor Settlement

agriflo by CRM Systems includes highly configurable, but easy to use producer settlement functionality. This functionality builds on the producer contracting functions in agriflo and can handle virtually any settlement terms and conditions.

agriflo by CRM Systems includes highly configurable, but easy to use producer settlement functionality. This functionality builds on the producer contracting functions in agriflo and can handle virtually any settlement terms and conditions.

The result is virtually effortless settlement, while not sacrificing the ability to make individual override adjustments when appropriate.

agriflo also generates CGC compliant scale tickets to finish the process off.

This short video explains the settlement process.

Receiving Commodities

agriflo by CRM Systems includes easy to use commodity receiving functionality that is accessible from within the Sage CRM environment.

Receipts can be processed based on bookings, or without bookings – depending on what is appropriate. The process is designed to be fast, easy, and virtually error proof, especially if you have control system or truck scale integration enabled.

This short video explains the receiving process.