The world is getting smaller!

The world is getting smaller in Agriculture. Globally processors are trading their products all around the world. As products move, information has to follow. Processors know that when they fill a sea container with product that is going overseas, there will be papers and information that will have to travel as well. In fact, sometimes the paperwork will have to beat the product shipment to the destination.

In the majority of cases, these documents have to be manually created and this can be a very time consuming process.

Being manual:

- You can experience errors and there maybe rework that happens.

- Or the error is not corrected at the processing facility and it can be flagged at another point in the supply chain which results in the shipment being delayed.

- Or worse, you can accidentally send the work and information to the wrong person.

Imagine how much time it can take to create the documents needed to move the product around the globe. Imagine the time taken to correct the documents if a mistake is made. What if you could automate this process, so that the documents needed to ship out the product happen automatically. Even better if you could automate with rules attached to different documents so that the correct documents can be generated for different situations. Simplifying your job and making this smaller world that much more enjoyable and reducing your stress.

This reality is available today with Agriflo systems. Agriflo can set up your shipment documents easily and effectively. Allowing you to do what you do best and that is processing products for your customers. Agriflo can save you time and money. With just a few mouse button clicks, the Bill of Lading, export documents and even your vessel documents can be created.

Another unique feature that is offered by Agriflo is that you can visually track your shipment if you are GPS enabled. This feature allows you to give your customer real-time information. Adding this feature to auto-generated documents you can have a real impact with your customers and show them that you can supply information as if they are just down the street from you!

If you want to learn more check us out at www.agriflo.biz

Or drop by and see us at Grain World – Booth #2. Hope to see you there!

Closing the loop for Workflows in Agricultural Processing

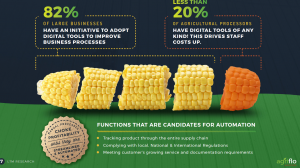

In Agriculture you hear phases such as “Industrial Internet of Things”, closing the loop on you data, and connecting to the supply chain. This can sometimes feel as if the world in Agriculture is finally catching up to technology or it can feel as if technology in agriculture is out of control. Either feeling ultimately comes down to your workflows and technology.

In Agriculture, efficiency of how we work comes to be a fact of life. If we touch the product too many times during processing, this will impact our margins. We know this as processors, but if you have learned to leverage your technology and enhance your workflows so that they are tightened up, it will allow you to be more efficient, increase your profitability and increase your volume into the supply chain.

By connecting the dots with your workflow and technology, it allows you to have better management in your data. This means you can actually use it to make real time decisions. Rather than trying to decipher what happened yesterday or last week and trying to piece everything together. If the workflow and the technology are working together, this will prevent workarounds and errors that can have an impact on your customers.

Workflow and technology working together can provide:

- Reduction in Human Errors or inconsistencies.

- Increase efficient operations for higher volume of output.

- Quicker processing in the agricultural Supply chain.

In the UK there was a recent study that showed that customers sited higher sales as one of the top benefits of using supply chain integrated technology which allowed them to tighten up the workflow processes.

The biggest challenge for the processor is that some off the shelf technology may have limitations in allowing the processor to maximize efficiency and may impact their bottom line. Hence why workflows may not be tightened up or there are just too many work arounds that will occur just to get the product out the door. This type of situation can actually hinder the through put of the plant.

In order to mitigate this scenario you will need to have your workflow and technology working as one. Certain software such as Agriflo has the ability to graphically illustrate your workflow to help you manage it throughout the process. Agriflo software will allow you to change that workflow so that you don’t have to change your software. It will allow you the capability to tighten up the workflows and increase your productivity. The software will grow with you. Agriflo really becomes an extension of your team.

If you would like to learn more!

Check us out: www.agriflo.biz

What is Agriflo?

We know and love agribusiness. We’d love to talk to you and learn more about your business.

Call us at 1-888-3444-2652, Follow us on twitter @agri_flo, or Find us on Linked-in, Facebook, or our website http://www.agriflo.biz !

The Agriculture Blockchain is here, today.

In my travels throughout the agriculture industry, I routinely talk to people who say things like “this tracking and tracing, and blockchain stuff is interesting, but it doesn’t affect me and won’t impact my business for many years in the future.” I can understand why they say that. So far, the agriculture supply chain has been fairly unaffected by the technological revolution that is hitting other industries. While on-farm technologies have started to take off – heck, we have fully robotic combines now that drive themselves – post-farm supply chain hasn’t seen the type of disruptive technology that others have.

Or so many people think. The reality, however is that these technologies are here, and they being deployed now, and those who do not implement them will be the buggy-whip manufacturers of the future.

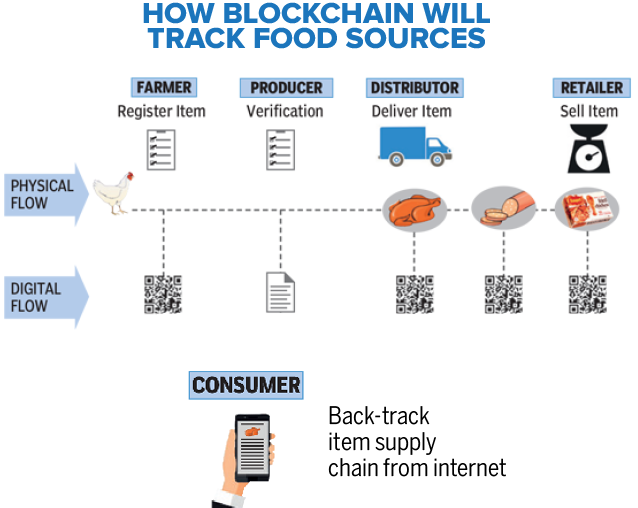

As an example. On Sept 24, 2018, Walmart announced that it will require all suppliers of fresh, leafy greens to trace their products back to the farm using blockchain technology.

“All fresh leafy greens suppliers are expected to be able to trace their products back to farm(s) (by production lot) in seconds – not days,” the company said in a letter to suppliers. “To do this, suppliers will be required to capture digital, end-to-end traceability event information.”

Direct suppliers are expected to have these systems in place by Jan. 31 and all “end-to-end” suppliers are expected to comply by the end of September 2019.

Meanwhile, national dairy cooperative Dairy Farmers of America (DFA) announced Sept. 25 that it is starting a pilot project intended to increase supply chain transparency and better connect farmer owners with customers.

“Consumers today want to know where their food comes from and blockchain technology, gives consumers real-time data, which can really help increase trust and confidence about food production from start to finish,” said David Darr, vice president sustainability and member services at DFA, in a press release.

Janette Barnard, sales and marketing director at DecisionNext, shares her expertise on digital value chains in agriculture, including blockchain technology.

“As the flow of information through the value chain becomes increasingly valuable, capturing, transferring, and using data will be a critical evolution in the grain industry,” notes one of her presentation previews. “In this session we’ll explore the dynamics around this shift and the skills, processes, systems and tools from predictive analytics to blockchain that will enable first movers to gain an edge in this new digital world.”

The fact of the matter is that field-to-plate digital tracking, and blockchain technologies are already having an impact in certain segments of the seed, feed, food and grain supply chains – and this change is accelerating at an incredible pace. Those organizations that do not prepare today for what is already happening, but will most surely be ubiquitous only a few years from now, will get locked out of markets for their products as customers, like Walmart, refuse to accept product that is not part of the chain.

The good news is Agriflo is ready today for these and other requirements. Contact us to find out more.

Agriculture, What Next?

- What’s Next

Agriculture, What’s Next?

As technology becomes an increasing part of our everyday lives, more and more examples can be found in the agriculture world. A great example of this can be found in precision agriculture where farm machinery is getting connected to artificial intelligence and with websites and the management of big data.

It can even be found in the processing of seed, feed, food and grain where technology is beginning to play an important role in processing with new tools of (AI) artificial intelligence and blockchain.

This technology can deliver instructions in a farmer’s native language, including when to sow their crops and has led to a 30% increase in yields for those farmers. This is an example of a successful ‘App’ which was created by using the Microsoft Cortana Intelligence Suite, which includes machine learning and is powered by people in order to create the optimal date/best time to sow.

Farmers who participated didn’t need to install any special apps on their devices and could receive the information via text messages. These farmers in India sowed their seeds early and the ‘App’ was especially helpful during monsoon season.

This is just one example of how AI can help farmers to actually utilize their seeds in an effective and timely manner to help them with increasing their yields.

Processors can use AI in a very similar manner, by learning how to effectively manage their plant’s times which will increase their rate of return on investment and/or increase their KPIs.

AI has the ability to examine the tasks that are being performed, look at the big data and then determine insights and make predictions. It can be as simple as taking a “snapshot” picture of a business and giving a diagnosis of what’s occurring in the plant and what needs to happen. Or it can be more complex with many different aspects of many different controls, ultimately helping your business to ensure that there is excellent quality in the plant.

Ultimately AI is the automation of tasks. These tasks and the information garnered from them will never get missed. AI doesn’t seek out the replacement of key individuals in your process, instead it enhances their industry and experience knowledge and allows better and innovative decision making which helps companies become highly effective with increased KPIs.

If you would like to learn more about Agriculture Technologies and Agriflo. Please contact us

Fully Integrated Systems

Fully Integrated Systems

What are the best reasons to have Fully Integrated Systems in Agriculture?

Fully Integrated Systems reduce the amount of re-entry and reduce the amount of re-work. By fully integrating your processes on the farm or in the processing facility, you are able to do more with less. By connecting the system to the shop, you can receive real-time information and gain the ability to make decisions very quickly which will increase KPIs. Within your facility this could be as simple as connecting your agris system to your accounting system or it could be as simple as having one central source of information. Studies have shown that manufacturers or processors can actually improve their business in terms of productivity and terms of financial gains by 30-40%.

Fully integrated systems actually help you in the tracing and tracking process, especially when the need is to quickly identify immediate issues. A closed loop system can actually minimize errors and allow you to work ON your business rather than IN your business.

In order for a closed-loop system to be successful, three key features need to be addressed. People, Processes and Tools. If you train your people to work within the closed loop system you will reduce re-work and reduce re-entry and this allows you to have the appropriate tools for decision-making to happen in a quick timeline. It will also help you uncover errors faster and give you the ability to deal with them as in a timely manner. A closed loop system can actually help you and your employees have a complete snapshot of your company.

If you would like to learn more about fully integrated systems or Agriflo. Please contact us